Case Study: Repeat Order for Minor Ingredient Batching System from South Korean Client – Crushing, Screening & Precision Batching, Globally Trusted!

Qingdao Zhonghaide Automation Equipment Co., Ltd., leveraging years of R&D and manufacturing expertise in automation equipment, has successfully delivered a custom minor ingredient batching system for a South Korean client. Tailored to the client’s specific production requirements, this project integrates core technologies such as automated control, precision metering, and high-efficiency conveying to achieve full-process intelligent operation of minor ingredient batching, demonstrating the international competitiveness of "Made in China" intelligent manufacturing.

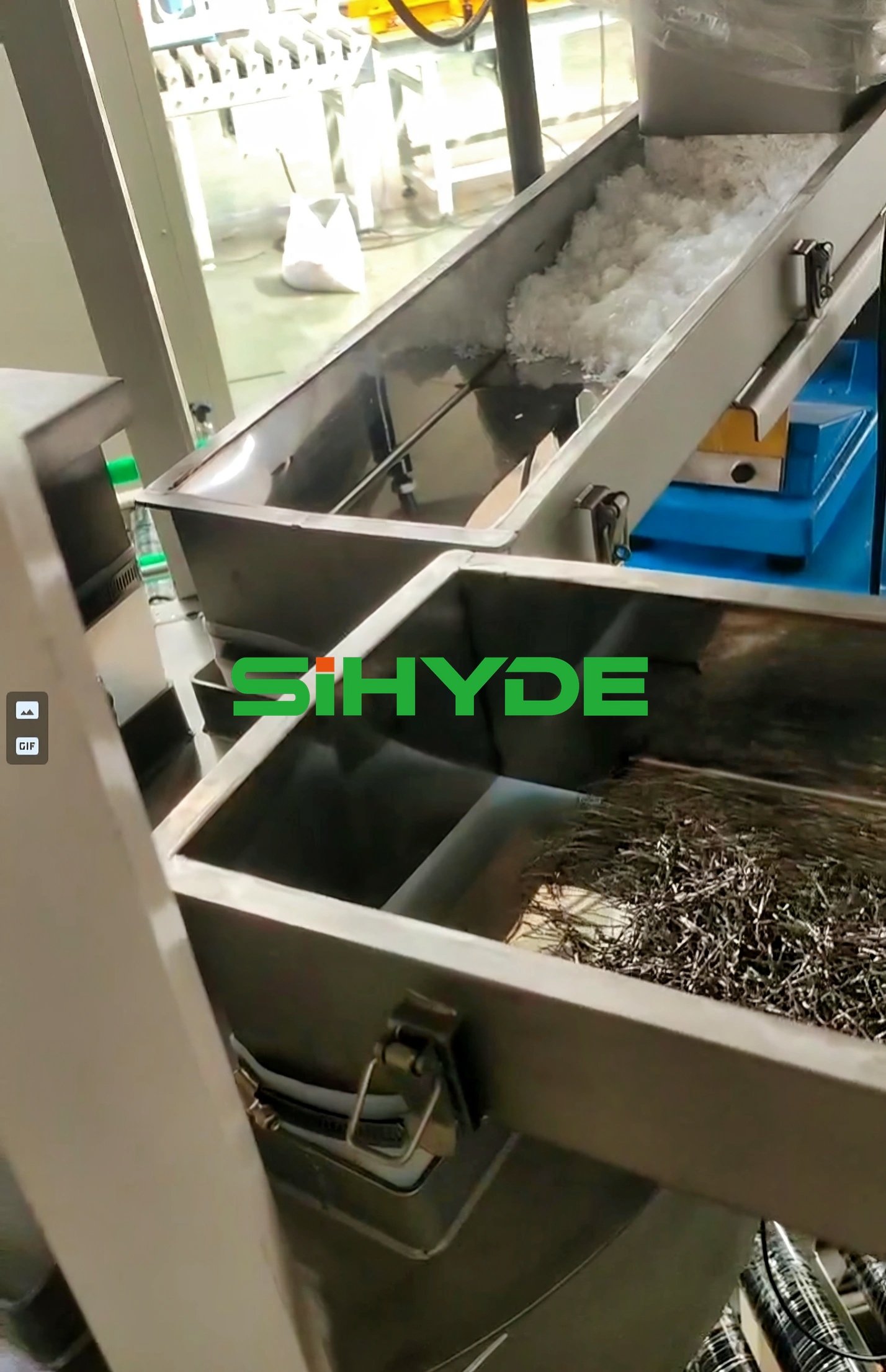

1. Multi-Module Feeding System: Flexible Adaptation to Diverse Materials

Differentiated Feeding Hoppers: Capable of handling multiple types of materials simultaneously, meeting the needs of complex production scenarios.

High-Quality Silos: Constructed with mirror-finish stainless steel, featuring corrosion resistance and easy cleaning to ensure material storage safety.

Intelligent Pretreatment Device: Equipped with professional crushing equipment and screening components at the feed inlet, effectively solving material agglomeration issues and ensuring smooth subsequent production processes.

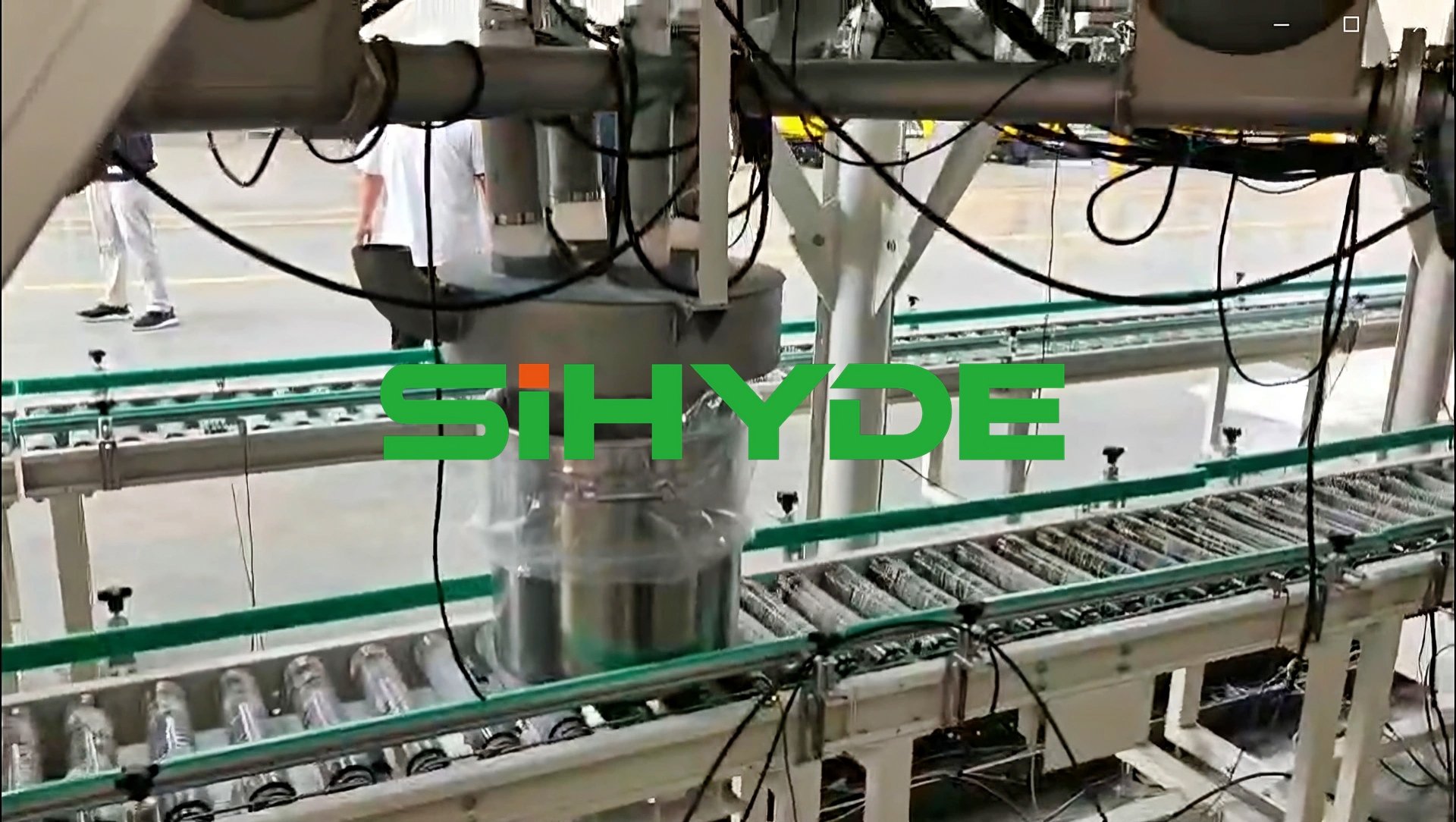

2. High-Efficiency Conveying System: Stable, Reliable & Precise Conveyance

Diversified Conveying Equipment: Integrates screw conveyors (including twin-screw design), belt conveyors, and turning belt conveyors to achieve comprehensive, dead-angle-free material circulation.

Intelligent Feeding Control: Equipped with professional vibration motors and electromagnetic vibration feeders, combined with precision control algorithms, ensuring stable and controllable material conveying volume to avoid accumulation or supply interruption.

Durability Assurance: Key conveying components are made of stainless steel and carbon steel; structural parts undergo precision welding and anti-corrosion treatment, adapting to long-term high-intensity production operations.

3. Intelligent Control System: Precision Metering & Automated Management

Professional Sensor Configuration: Adopts branded rotary level switches for real-time monitoring of silo material status, paired with high-precision load cells to realize dynamic material monitoring and precision metering.

High-End Electrical Control Components: Equipped with internationally renowned PLCs, electrical components, and industrial-grade computers, building a stable and reliable control system architecture to ensure continuous equipment operation stability.

Pneumatic Control Solution: Utilizes well-known pneumatic components to achieve rapid response and precise control of actuators such as valves and gates, with high operational sensitivity.

4. Automation Level: Full-Process Intelligent Management

Achieves unmanned operation from material feeding, pretreatment, conveying to metering, reducing manual intervention, minimizing human errors, and improving production consistency.

Equipped with a professional dust removal system and pneumatic control system, effectively controlling dust concentration in the production environment, complying with environmental protection requirements, and ensuring operator health and safety.

Supports real-time data monitoring and parameter adjustment, enabling flexible process optimization based on production needs and adaptation to multi-category product switching.

5. Customized Design: Precise Matching of Client Requirements

Tailored equipment configuration and spatial layout solutions based on the client’s production site layout, capacity planning, and material characteristics.

Optimized pretreatment, conveying, and metering process parameters for the physical properties of different materials, ensuring accurate batching ratios.

Reserved functional expansion interfaces to facilitate subsequent capacity enhancement and technological upgrading, extending equipment service life and reducing clients’ long-term investment costs.