Automatic packaging and palletizing - palletizing methods of palletizing machines

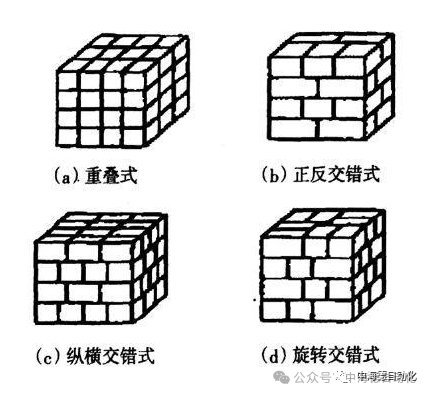

1. Overlapping: In the so-called overlapping stacking method, the arrangement of goods on each layer is exactly the same, and a cargo unit is formed by many closely stacked columnar bodies. Making the shape of the cargo box embedded in the overlapping type is a measure to prevent inter-layer movement.

Because the layers of this stacking method are arranged in the same way and there is no cross-lapping at all, the cargo unit is often prone to longitudinal splitting and poor stability. When stacking high in this way, other stabilization measures must be taken, usually by adding wrapping film, waist hoop and other methods to fix it.

2. Positive and negative staggered: This method is the same as the bricklaying method, with good overlap between layers and high stability of the goods. This method is mostly used for rectangular pallets.

3. Criss-cross type: This is the stacking of odd and even layers on the pallet in different directions. This method can only be effectively used for square pallets. Its operation is relatively simple, and there are overlaps between the layers. It is a better method, especially when using an automatic palletizer.

4. Rotational staggered type: This method changes the direction 90 degrees to form an overlap when stacking each layer to ensure stability. However, due to the easy formation of holes in the center, the surface utilization rate of the pallet is reduced. Stacking strength and stacking load stacking strength refers to the load that the corrugated cardboard packaging stored in the warehouse can withstand before it collapses when stacked under static pressure. Stacking strength can be tested through stacking strength experiments, and can also be estimated by testing compressive strength.